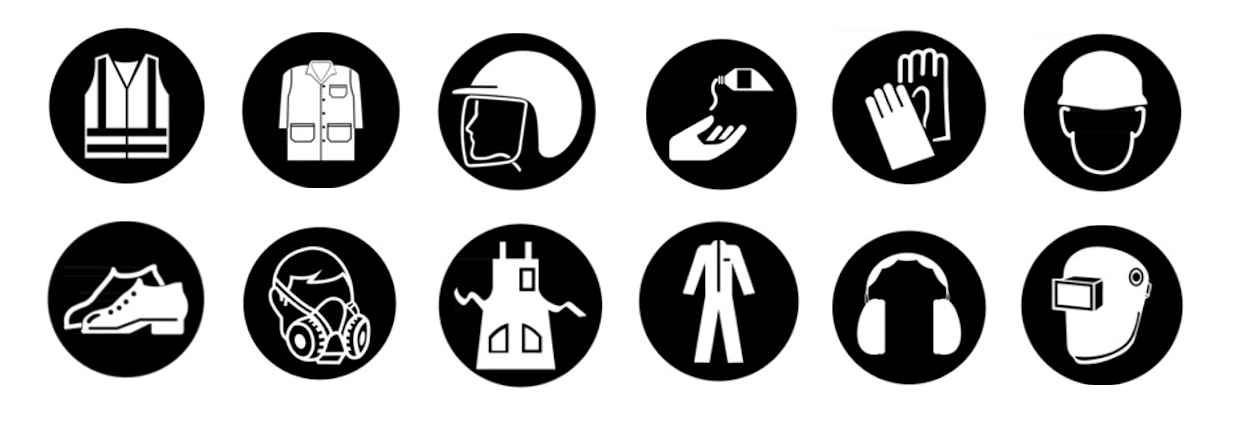

Choosing the correct Personal Protection Equipment for the task.

Otherwise known as PPE.

Selecting the appropriate type of PPE depends on the specific hazards present in the workplace. It is crucial to conduct a thorough hazard assessment and choose PPE that provides adequate protection while ensuring comfort and ease of use.

Refer to our Quick Quide to common workplace PPE items and their uses:

Head Protection

Type | Use |

|---|---|

Hard Hats |

Classes of Hard Hats

|

Safety Helmets |

|

Bump Caps |

|

Welding Helmets |

|

Electrically Insulating Helmets |

|

Key Considerations for Choosing Head Protection

Hazard Assessment: Identify potential hazards such as falling objects, electrical risks, or exposure to extreme temperatures.

Regulatory Compliance: Ensure head protection equipment complies with relevant safety standards and regulations.

Comfort and Fit: Adjustable suspension systems and padding options for a customizable and comfortable fit.

Compatibility: Ensure head protection can be effectively combined with other required safety equipment.

Workplace Body Protection

Type | Use |

|---|---|

Disposable Coveralls |

|

Reusable Coveralls |

|

Chemical-Resistant Aprons |

|

Heat-Resistant Aprons |

|

Hazmat Suits |

|

Fire-Resistant Suits |

|

High-Visibility Clothing (Reflective Vests etc) |

|

Flame-Resistant Coveralls and Jackets |

|

Antistatic Clothing |

|

Arc Flash Clothing |

|

Medical Protective Clothing |

|

Workplace Footwear

Type | Use |

|---|---|

Steel-Toe Boots |

|

Composite-Toe Boots |

|

Metatarsal Boots |

|

Electric Hazard (EH) Footwear |

|

Slip-Resistant Shoes |

|

Waterproof Boots |

|

Insulated Boots |

|

Chemical-Resistant Boots |

|

Puncture-Resistant Boots |

|

Fall Protection

Type | Use | |

|---|---|---|

Full-Body Harnesses |

| |

Lanyards |

| |

Self-Retracting Lifelines (SRLs) |

| |

Anchor Points |

| |

Vertical Lifelines |

| |

Rope Grabs |

| |

Fall Arrest Systems |

| |

Guardrails |

| |

Safety Nets |

|

Hand Protection

Type | Use |

|---|---|

Disposable Gloves |

|

Cut-Resistant Gloves |

|

Chemical-Resistant Gloves |

|

Heat-Resistant Gloves |

|

Leather Gloves |

|

Lone Worker Device

Type | Use |

|---|---|

Panic Button |

|

GPS Tracking Device |

|

Man-Down Alarm |

|

Two-way Communication Device |

|

Hearing Protection

Type | Use |

|---|---|

Ear Plugs |

|

Ear Muffs |

|

Canal Caps |

|

Eye and Face Protection

Type | Use |

|---|---|

Safety Glasses |

|

Goggles |

|

Face Shields |

|

Welding Helmets |

|

Respiratory Protection

Type | Use |

|---|---|

Dust Masks |

|

Half-Face Respirators |

|

Full-Face Respirators |

|

Powered Air-Purifying Respirators (PAPRs) |

|

Self-Contained Breathing Apparatus (SCBA) |

|

N95 Respirators |

|

Weather Protection

Type | Use | |

|---|---|---|

Rain Gear |

| |

Insulated Clothing |

| |

Sun Protection |

| |

Wind-Resistant Jackets |

| |

Thermal Socks |

|

Miscellaneous Protection

Type | Use |

|---|---|

High-Visibility Clothing |

|

Back Supports |

|

Knee Pads |

|

Cooling Vests |

|

First Aid Kits |

|

Maintaining your PPE Register

Employers must ensure employees have the appropriate PPE and that it’s in good condition. Schedule regular checks to maintain compliance with New Zealand’s Health and Safety at Work Act 2015. Employers are responsible for providing PPE, while employees must wear it correctly. Failure to comply can result in fines.

Responsibility and Compliance

Employers: Must provide necessary PPE.

Employees: Required to wear and use PPE correctly.

Fines: Non-compliance can lead to significant fines.

If you don’t have a PPE register, contact one of our friendly OSHbox consultants for assistance.